“Reduce, Reuse, Recycle” vs. Bioplastics

Plastics have become an integral part of our lives, and they are everywhere. They are in our clothes, our cars, our homes, and even in our food. However, the widespread use of plastics has led to significant environmental issues, and the carbon footprint of plastics is enormous. To address these issues, bioplastics have been presented as a sustainable solution, but they also come with their set of disadvantages. So, should we pursue plastic reduction or bioplastics? We assert that the idea of “Reduce, Reuse, Recycle” is a better way to reduce carbon emissions.

What are bioplastics?

Bioplastics are a type of plastic that is made from renewable biomass sources, such as corn starch, sugarcane, and potatoes, instead of petroleum-based sources. The primary benefit of bioplastics is that they are made from renewable resources and are biodegradable, which means they can be broken down by natural processes. Bioplastics have been hailed as a sustainable alternative to traditional plastics, and they have gained popularity in recent years.

Disadvantages of bioplastics

- Production process: The production process of bioplastics requires significant amounts of energy and resources, and it often involves the use of chemicals and water. This process can lead to environmental issues, such as water pollution, land degradation, and air pollution.

- Land use: The production of bioplastics requires significant amounts of land to grow the crops needed to produce the raw materials. This can lead to deforestation and land-use changes that can harm biodiversity.

- Recycling challenges: Bioplastics cannot be recycled in the same way as traditional plastics, which means they often end up in landfill or incinerated, which contributes to greenhouse gas emissions.

- Biodegradability challenges: While bioplastics are biodegradable, they often require specific conditions to break down, such as high temperatures and specific enzymes. In landfill or the ocean, they may not break down, leading to the persistence of plastic pollution.

The “Reduce, Reuse, Recycle” approach

Bioplastics have been presented as a sustainable alternative to traditional plastics, but they come with their set of disadvantages. While they may seem like a promising solution, they do not address the root problem of plastic pollution, as mentioned above. The “Reduce, Reuse, Recycle” approach is a better way to reduce carbon emissions and address the plastic pollution problem. By reducing our consumption of single-use plastics and reusing items, we can reduce the amount of plastic waste that ends up in landfill or the ocean. Recycling also plays a crucial role in reducing carbon emissions by reducing the need for virgin plastic production. With these three R’s, we can reduce the amount of plastic waste that ends up in landfill or the ocean, and we can help reduce the need for virgin plastic production.

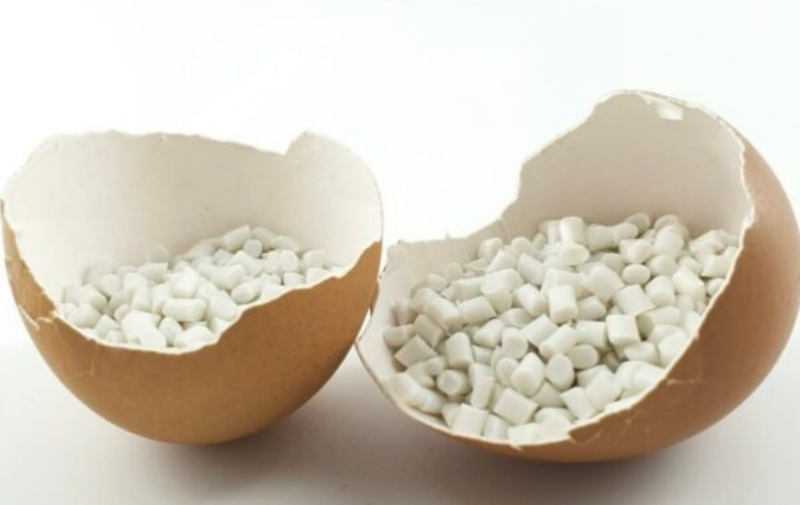

This is where GEX really shines as a carbon reducer. GEX bio-calcium from eggshells not only cleans up an agricultural waste, but also uses it to reduce plastic content in products by up to 50%. More, the end product is recyclable itself, and GEX can also be used to create reusable products. It is clearly the epitome of the “Reduce, Reuse, Recycle” approach. Check our website here for more information, and check the patent owner’s site for a list of potential products that can be made with GEX.

No Comments

Sorry, the comment form is closed at this time.